Table of Contents

Methods of Polymerization: Polymerization would be any chemical process in which relatively small molecules, known as monomers, combine to form a very large chainlike or network molecule known as a polymer. A monomer molecule could be identical, or they could represent two, three, or more different compounds. To make a product with certain unique physical properties—such as elasticity, high tensile strength, or the ability to form fibres—that distinguish polymers from substances composed of smaller and simpler molecules, at least 100 monomer molecules must be combined; many thousands of monomer units are often incorporated in a single molecule of a polymer. The composition covalent chemical bonds between the monomers distinguishes polymerization from other processes such as crystallisation, in which large numbers of molecules aggregate due to weak intermolecular forces.

Polymerization happens when several monomers combine chemically to form three-dimensional networks or a chain of elements. Monomers can be the same or different compounds that are combined to form a polymer. Furthermore, for a polymer to have distinct properties, it must be formed by the combination of at least 100 monomers. A polymer molecule is typically made up of hundreds of thousands of monomers. In this article, we shall discuss the Methods of Polymerization.

Overview

In the case of polymerization, a stable covalent bond is formed, which aids in the formation of polymers with distinct properties. This includes high tensile strength, elasticity, and fibre formation capability.

In fact, polymerization can happen in chemical compounds through a variety of reaction mechanisms that vary in complexity due to the functional groups present in the reactants and their inherent steric effects. In case of more straightforward polymerizations, alkenes form polymers through relatively simple radical reactions; however, reactions involving substitution at a carbonyl group require more complex synthesis due to the way reactants polymerize. Alkanes could be polymerized as well, but only with the assistance of strong acids.

Even though alkenes can polymerize in somewhat straightforward radical reactions, they form useful compounds such as polyethylene and polyvinyl chloride (PVC), which are produced in high tonnages each year due to their utility in commercial product manufacturing processes such as piping, insulation, and packaging. Polymers including such PVC are called “homopolymers” because they are made up of repeated long chains or structures of the same monomer unit, whereas polymers made up of more than one monomer unit are called copolymers (or co-polymers) (or co-polymers).

Polymers seem to be massive molecules formed when monomers are linked together in a chemical reaction known as polymerization. Polymerization reactions are classified into two types: addition reactions and condensation reactions.

Typically, two types of polymerization are distinguished. Each step of the condensation polymerization process is accompanied by the formation of a molecule of some simple compound, most often water. Furthermore, during polymerization, monomers react to form a polymer without the formation of by-products. Addition polymerizations are typically carried out in the presence of catalysts, which in some cases exert control over structural details that have significant effects on the polymer’s properties.

Methods of Polymerization: Polymerization techniques

Below explained are the methods of polymerization:

Addition Reactions:

Monomers are linked with double bonds in addition polymerization reactions. One of the monomers’ double bonds breaks and is linked to the neighbouring monomer. The whole process is repeated until monomers are formed. Some polymers may be made up of thousands of polymers. The creation of a polymer by addition polymerization is an example of a chain reaction. If this reaction is started once, it will continue on its own. This reaction’s main steps are initiation, propagation, and termination. Many processes are used to carry out the chain reaction of addition polymerization, and the details of the reactions vary greatly depending on the methods employed. Only alkene polymerization is considered an addition reaction. Condensation polymerization reactions are slower than addition polymerization reactions. There are some techniques:

- Solution Polymerization: Under this industrial polymerization method, a monomer is dissolved in a non-reactive solvent containing an initiator or catalyst that accelerates the reaction. The polymer formed as a result of the process is also soluble in the same non-reactive solvent.

- Bulk Polymerization: This is also known as mass polymerization and is created by introducing a radical initiator into a pure monomer. The monomer, on the other hand, must be liquid, and the radical initiator must be soluble and the reaction is exothermic.

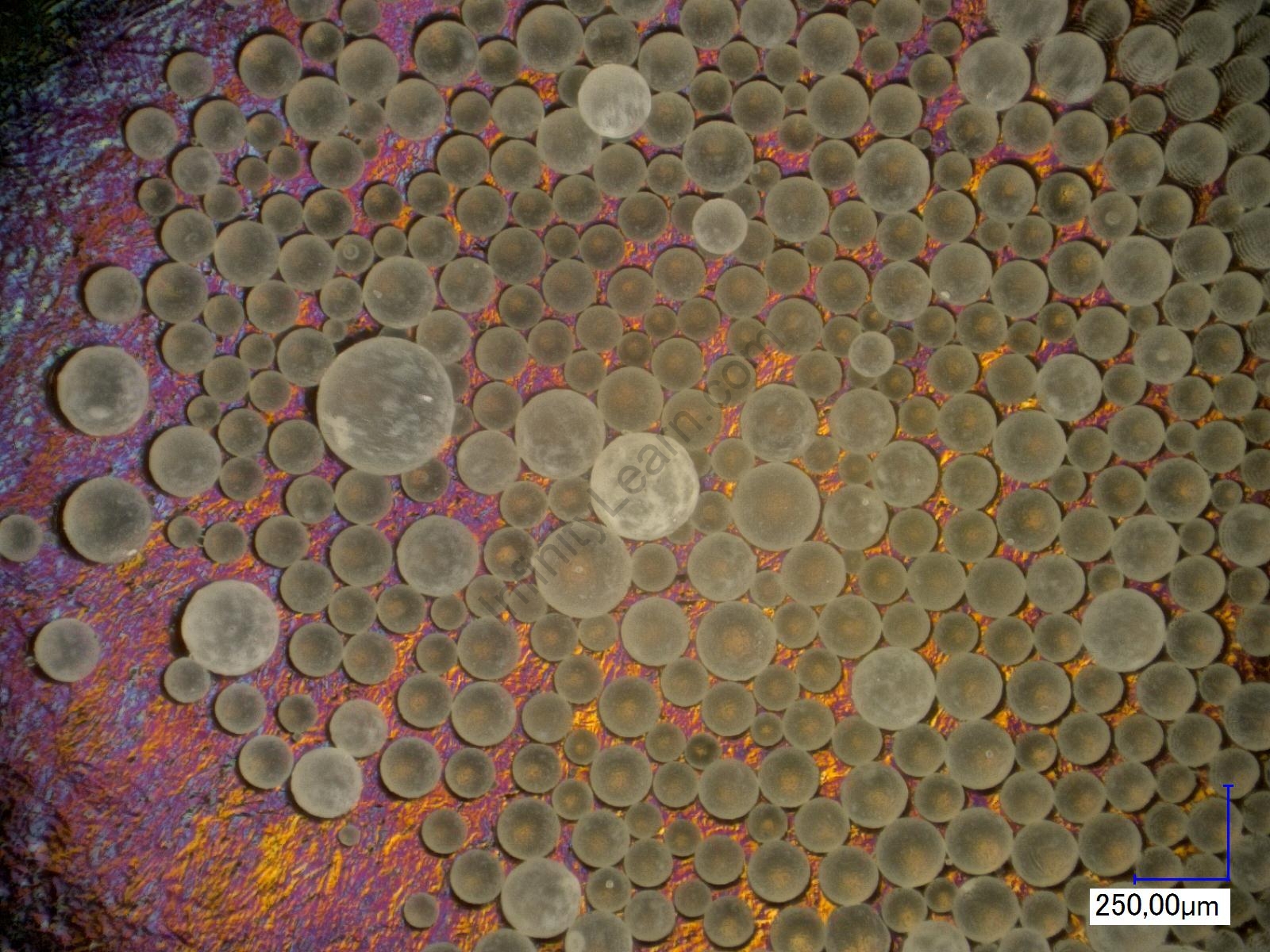

- Emulsion Polymerization: This is a radical polymerization process involving a monomer, water containing an emulsion, and a surfactant.

- Suspension Polymerization: Mechanical agitation is used in this heterogeneous radical polymerization process to mix monomers in their liquid state.

Condensation Polymerization:

Monomers react with one another during condensation polymerization, resulting in the release of a small molecule. This small molecule is commonly hydrochloric acid or water. Numerous polymers are bunched together, resulting in the formation of solid plastic. The polymers are held together by weak forces and can be easily disrupted by the application of heat. One such plastic, known as thermoplastic, is easily melted. Condensation polymerization is the process by which condensation polymers are formed. Many useful and important polymeric materials, including radicals, which are reactive species, cannot be produced by chain-growth processes. Instead, their formation is facilitated by the transformations of the polyfunctional reactants’ conventional functional groups. Condensation polymers include the polyamide Nylon 66 and the polyester Dacron. In general, these polymers grow through the formation of carbon-heteroatom bonds. These polymers are also known as alternating copolymers, and the combined moiety is defined as the monomeric unit that is continuously repeated. Naturally occurring condensation polymers include polypeptide chains from proteins and cellulose. These reactions, in general, have a lower molecular weight and frequently necessitate the use of heat. The groups of shorter chains are combined into longer chains in the late stages of the polymerization reaction because the chain has a terminal functional group that remains active.

Final Thoughts

The sector of polymers is so vast, and the applications so diverse, that understanding how polymers are made and used is critical. Because there are over 60,000 different plastics competing for a market share, understanding this important field can truly enrich our appreciation of this wonderful material. Numerous polymerization methods were investigated in order to develop living polymerization procedures for the preparation of side-chain liquid crystalline polymers with well-defined molecular weight distributions.

FAQs

What is polymerization?

Polymerization seems to be the procedure by which larger macromolecules are formed from smaller subunits known as monomers.

What are the two methods of polymerization?

Polymerization can be classified into two types: chain-reaction (or addition) polymerization and step-reaction (or condensation) polymerization.

What is the mechanism of polymerization?

A proton acid is added to aziridine to produce the corresponding aziridinium ion in the polymerization mechanism.

Infinity Learn App

Now you can find answers to all your subject queries & prepare for your Exams on our Ultimate Learning App for Classes 6 to 12 – Infinity Learn.