Courses

By Shailendra Singh

|

Updated on 5 Dec 2024, 13:05 IST

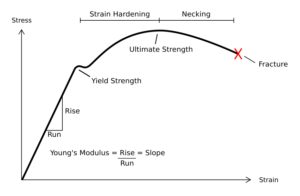

The stress-strain charts for various materials might seem very different. Brittle materials are robust because they can endure a great deal of stress, don’t extend much, and break quickly. The stress-strain relationship in ductile materials is linear in the elastic zone, but the linearity breaks down at the first turnover (the elastic limit), and the material could no longer return to its former form.

The tensile strength is the second peak, and it informs us how much stress a material can bear before breaking. Plastic materials really aren’t particularly strong, yet they can withstand a great deal of stress. The gradient of the line in a stress-strain plot determines Young’s modulus.

Giordano Riccati, an Italian scientist, did the very first research using the notion of Young’s modulus through its modern incarnation in 1782, 25 years before Young’s study. The word modulus comes from the Latin word modus, which means measure.

Recognizing when an object or material will flex or break is one of the most critical tests in engineering, and the property that informs us of this is Young’s modulus. It is a measurement of a material’s ability to stretch and distort.

The ratio of tensile stress to tensile strain is defined as Young’s modulus (E), a material parameter that tells us how easy it can stretch and flex. Where stress refers to the amount of force applied per unit area (F/A) and a strain refers to the amount of extension per unit length (d l/l).

The Young’s modulus of a wire can be calculated by monitoring the change in length (d l) as weights of mass m are imposed (assuming g = 9.81 metres per second squared).

E=σ/ϵ

E ≡ σ(ϵ)/ϵ =(F/A) / (ΔL/ L0) = FL0 /AΔL

The Young’s Modulus Formula has the following notations/units:

In engineering and materials science, a stress-strain curve for material is being used to depict the stress-strain-strain- strain relationship. It’s calculated by gradually increasing the load on a test coupon and measuring deformation, which can then be used to calculate stress and strain.

Stress-strain curves depict the displacement of a substance in response to a tensile, compressive, or torsional force. When evaluating various materials based on how they react to various loads, this is extremely important. Mechanical properties are the physical attributes that a substance exhibits when it is subjected to forces.

Mechanical properties comprise modulus of elasticity, tensile strength, elongation, toughness, and fatigue limit. The mechanical properties of the material would be those that control how it responds to applied loads.

Students should study all of the major chapters of the NEET curriculum to get the best results on the NEET test. Infinity Learn’s important questions for NEET are one of the most trustworthy study aids because they cover all of the main concepts in the syllabus. Additionally, these crucial questions are created from previous year’s question papers, taking into account the importance of each chapter in the curriculum.

Physics is one of the most significant courses for the NEET entry exam, and it is a required topic for which you must study. Infinity learn makes it easier to study Physics for NEET; the revision notes provided by infinity learn experienced staff is the best notes available for the Physics subject young’s modulus. Young’s modulus NEET Big Problems can be downloaded for free to help you prepare for your final exam.

Steel is one of the materials with the greatest flexibility.

Ductility is indeed the material property that allows it to be pulled to a smaller portion when tensile stress is applied

The SI unit for Young's modulus is Pascal.

The stress-to-strain ratio below the limit of proportionality is defined as elastic modulus. It is a measurement of the rigidity or stiffness of a substance. The stiffer the material is, or the lower the elastic strain induced by a given load, the higher the modulus.