Table of Contents

A screw gauge, also known as a micrometre, is a measuring instrument made out of a calibrated screw that is used to take measurements of small objects. A screw gauge is a type of meteorological instrument that is used in machining, mechanical engineering, and other applications. The first screw gauge was created in the 17th century by William Gascoigne, who modified a vernier calliper so that it could be used in a telescope to calculate distances among stars and other celestial bodies. Henry Maudslay created a bench micrometre, a stronger form of a screw gauge with a cast-iron frame.

A brief outline

A differential screw is a crucial component of an analogue screw gauge that enables the observation of small magnitudes. These screws have a number of threads, each of which corresponds to axial movement when spun one at a time. That is, each 360 0 spin of the screw spans a very small axial distance. This distance is alluded to as the screw’s lead or pitch. Even if the object to be measured is very small, the size of the object can be determined by turning the thimble, which rotates the screw. The minute dimension is transformed into larger rotations that are much easier to comprehend. The measurement of the thing examined is displayed on a Display screen in electronic screw gauges.

Important concepts

Measurement with a screw gauge Using a Microscope

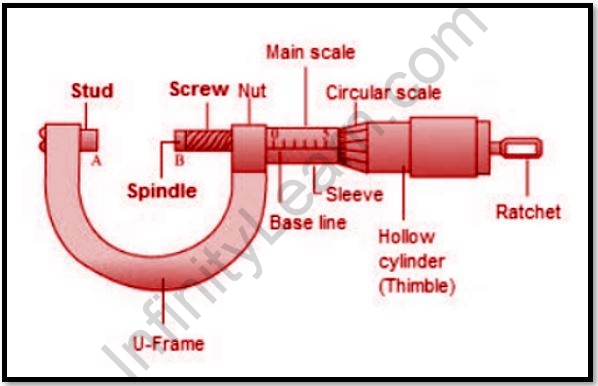

- Get to know the components of a Screw Gauge: Some sections, such as the Sleeve, Anvil, Spindle, Thimble Lock, Frame, Thimble, and Ratchet Stop, are adjustable while others are fixed.

- Clean the spindle and anvil before beginning to measure: Place a piece of paper or a clean towel between the spindle and the anvil. Squeeze the setup slightly till the paper or cloth becomes stuck, then pull it out while cleaning the setup. This step is optional; however, it aids in obtaining an exact measurement because precision is essential.

- Place the thing between the anvil and the spindle: Carefully place the thing between the anvil and the spindle. Because the anvil is inherently stationary, place the thing against it. The object should have been properly positioned so that it would not move while the measurements are taken.

- To tighten the ratchet counter, turn it clockwise, making that the thimbles zero are parallel to the scale line on the sleeve.

- Tighten the spindle in the middle with the object: When you rotate the thimble, it clicks. Increase the effort until it clicks three times.

- While the object is in the middle, lock the thimble: Even though the thimble is locked, the spindle can be moved.

- Carefully remove the object: If the screw gauge is scratched or shaken, the accuracy will be impaired, therefore make sure to avoid this.

- Once you unlock the spindle, make a mental note of the following: If the single setup loosens, remeasure the entire setup.

The formula for Screw Gauge

In every screw gauge, there are two main parameters that are employed. They are the screw gauge’s pitching and least count.

Pitch: The distance travelled by the spindle per revolution is measured by sliding the head scale over the pitch scale in order to accomplish one full rotation of the screw gauge.

Pitch of the screw gauge = (distance moved by a screw)/ (no. of rotations given)

The screw’s least count is defined as the distance travelled by the screw’s tip when it is spun through one division of the head’s scale.

Least count (LC) of the screw gauge = (pitch)/ (total no. of divisions on the circular scale)

A micrometre screw gauge is a device for assessing the diameter of thin wires and the thickness of tiny sheets like glass or plastics.

Least count of micrometer = 1mm/100 = 0.01 mm

Using a Screw Gauge

- While holding the object to be measured, apply slight pressure between the anvil and spindle of the screw gauge.

- Take note of the circular scale’s initial reading just before zero. The major scale reading is what it’s called (M.S.R.).

- It is necessary to record the number of circular scale divisions (n) that coincide with the main scale line. Circular scale reading (C.S.R.) – n X least count

- Combine the MSR and the CSR to get readings.

- Subtract the zero inaccuracy from the above reading to get the proper result.

Significance of screw gauge in IIT JEE exam

The questions in the physics part of JEE exams are usually dependent on conceptual understanding of the topic. To do well on the exam, you must have a strong conceptual foundation as well as the ability to apply principles in practice. The majority of the problems were meant to measure conceptual understanding. There were 13 questions from the class 11th syllabus and 17 questions from the class 12th syllabus in terms of number. This part included 20 moderate, 6 easy, and 4 difficult questions about electromagnetic waves, instrumentation systems, and a ray of reflection, among other topics.

FAQs

The micrometre screw gauge allows for even more precise measurements than the Vernier callipers. On the micrometre screw gauge, an auxiliary scale (measured tenths of a millimetre) on a rotary thimble is also employed.

In a nutshell, the ratchet acts as a torque limiter by applying a force while sliding at a preset torque. The spindle cannot move any further as a result of this. Some screw gauges, in addition to having scales that are locked in place, also have locking systems that prohibit any form of inaccuracy during the reading process.

If you need a more precise measurement, a micrometre screw gauge is recommended. It can measure items as small as a few millimetres in diameter and is typically accurate to 0.01 millimetres. What is a micrometre screw gauge used for?

Why is there a ratchet on the micrometre screw gauge?

Is the reading on the micrometre screw gauge accurate?