Table of Contents

Introduction:

The electrical resistivity and conductivity of materials are important properties. The conductivity and resistivity of various materials vary. The electrical conductivity of a material is determined by its electrical transport qualities. These can be measured in a variety of ways with a range of devices. When electricity flows freely through a material, it is said to have high conductivity. Copper and aluminum are two materials with excellent conductivity. The electrical conductivity of a material is a measurement of how easily electricity passes through it.

Let us know more about them in detail!

- Electrical Conductivity

The ability of a material to transmit a current, or the amount of electrical current it can carry, is measured by its electrical conductivity. Electrical conductivity is also known as specific conductance. Conductivity is a material’s intrinsic property.

- Electrical Conductivity Units

Electrical conductivity is measured in siemens per meter (S/m) and is symbolized by the symbol ?. Specific conductance is a measure of conductivity in water that is compared to that of pure water at 25°C.

- Electrical Resistivity

Electrical resistivity is a feature that is unique to each material and must be understood prior to the creation and design of electrical and electronic systems. Understanding how materials differ in resistivity can help you choose the right materials for your motors, electrical circuits, dielectrics, resistive heating, and superconducting projects.

Resistivity Unit

Electrical resistivity is a measure of the resistance of a specific material of a certain size to the electrical current conduction that travels through it and is represented by the Greek letter ⍴(rho).

Relationship between Electrical Resistivity and Electrical Conductivity

The properties of conductivity and resistivity are inversely proportional. Resistivity is high when conductivity is low. Conductivity is high when resistance is low. The following is the equation:

ρ=1/σ

Resistor Color Coding

Resistors come in a variety of shapes and sizes, and they can be used in both electrical and electronic circuits to control current flow or induce voltage drops in a variety of ways. However, the actual resistor must have some type of “resistive” or “resistance” value in order to accomplish this. Resistors come in a variety of resistance values ranging from fractions of an Ohm Ω to millions of Ohms.

Apparently, having resistors of every possible value, such as 1Ω, 2Ω, 3Ω, 4Ω, 5Ω, 6Ω and so on, would be impossible because literally tens of thousands, if not tens of millions, of different resistors would be required to cover all potential values. Instead, resistors are made in “preferred values,” with the resistance value inscribed in colored ink on the resistor’s body.

When the resistor’s body is large enough to see the print, such as large power resistors, the resistance value, tolerance, and wattage rating are usually displayed as numbers or letters on the resistor’s body. However, when the resistor is small, such as a 1/4 watt carbon or film type, these specifications must be displayed in a different way because the print would be difficult to see.

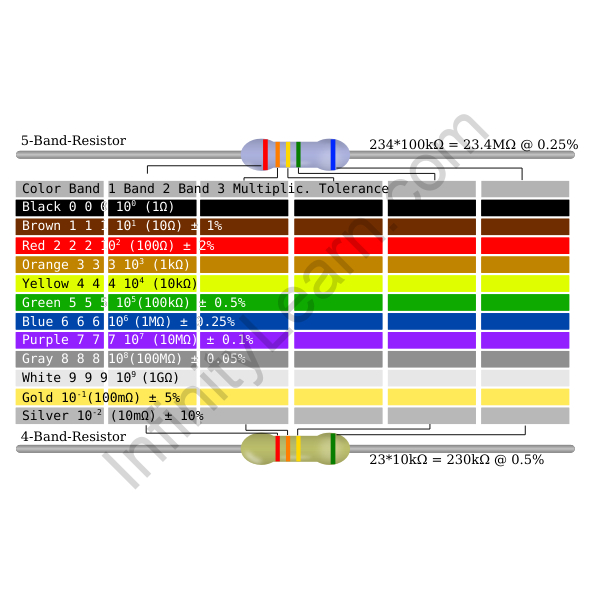

To address this, small resistors use colored painted bands to represent both their resistive value and tolerance, with the resistor’s physical size indicating its wattage rating. The Resistors Color Code is a system of identification created by these colored painted bands.

Many years ago, an internationally and internationally acknowledged resistor color code scheme was devised as a quick and easy way to identify a resistor’s ohmic value, regardless of its size or condition. Each digit of the resistor’s value is represented by a group of distinct colored rings or bands in spectral order.

The resistor color code marks are always read one band at a time, from left to right, with the bigger width tolerance band on the right side showing its tolerance. The first digit is recognized by matching the color of the first band with its related number in the digit column of the color chart below, and this reflects the first digit of the resistance value.

We acquire the second digit of the resistance value by matching the color of the second band with its associated number in the digit column of the color chart, and so on. The color-coding of the resistor is then read from left to right.

Calculating Resistors Value

The “left-hand” or most significant coloured band is the one closest to a connecting lead, with the colour coded bands read as follows from left to right:

The “left-hand” or most significant coloured band is the one closest to a connecting lead, with the colour coded bands read as follows from left to right:

Digit, Digit, Multiplier = Color, Color× 10color Ω

For example, a resistor has the following marking

Red Violet Red

272=27×10²=2700Ω

Factors Determining Resistivity of materials:

- Temperature

Temperature affects the resistivity of materials. The resistance of most metals increases as the temperature rises. The following formula calculates the change in resistivity of a material as a function of temperature:

ρt2=ρt1[1+α1(t2-t1)]

Metals’ resistance increases as the temperature rises. The metals have a positive temperature coefficient of resistance, which means they are resistant to heat. At temperatures close to absolute zero, certain metals exhibit zero resistivity. “Superconductivity” is the name given to this occurrence. As the temperature rises, the resistivity of semiconductors and insulators decreases. The term “negative temperature coefficient of resistance” refers to semiconductors and insulators that have a negative temperature coefficient of resistance.

- Mechanical Stressing

Mechanical stressing of a material’s crystal structure causes localized strains in the crystal structure. The passage of free electrons through the material is disrupted by these localized stains. The material’s resistivity rises as a result of this. As a result, annealing metal lessens the metal’s resistance. Metal annealing relieves mechanical stress on the material, allowing localized stains to be eliminated from the metal’s crystal structure. As a result, the metal’s resistivity decreases.

- Age Hardening

Age hardening is a heat treatment method that improves the yield strength of alloys and improves their capacity to resist permanent deformation by external forces. Precipitation hardening is another name for age hardening. By introducing solid impurities called precipitates, this method improves the strength of alloys. These solid impurities or precipitates disrupt the crystal structure of the metal, interrupting the flow of free electrons through it and increasing the metal’s resistivity.

- Cold Working

The manufacturing method of cold working is used to strengthen the strength of metals. “Work hardening” or “Strain hardening” are other terms for cold working. Cold working is a technique for increasing a metal’s mechanical strength. The crystal structure of metals is disrupted by cold working, which interferes with the migration of electrons in the metal, increasing its resistivity.

- Alloying

Alloying is the term for a solid mixture of two or more metals. Metals are alloyed to attain certain mechanical and electrical properties. In comparison to pure metals, the atomic structure of a solid solution is uneven. As a result, the electrical resistivity of the solid solution increases more rapidly as the alloy content increases. A little amount of impurity can significantly increase the metal’s resistivity. Even a low-resistivity impurity raises the base metal’s resistivity significantly.

Electrical resistivity and conductivity are essential properties of materials. Different materials have different conductivity and resistance. A material’s electrical conductivity is determined by its electrical transport properties. These can be measured using a variety of equipment in a variety of ways. A material is said to have high conductivity when electricity flows readily through it. Copper and aluminum are both excellent conductors of electricity. A material’s electrical conductivity is a measurement of how easily electricity can move through it. Resistor color-coding makes it easy to see a resistor’s resistive value and percentage tolerance by using colored bands.

Also read: Important Topic of Physics: Specific Heat Capacity

Frequently Asked Questions

Question 1: Is the wire’s resistance the same as it is when the temperature changes?

Ans: Metals’ resistivity changes with temperature. Although practically all alloys increase in resistance as temperature rises, the rate of change is slower than that of metals.

Question 2: How do you memorize color codes for resistance?

Ans: A mnemonic technique can be used to recall the resistor color codes. The capital letters represent the first letters of the colors, and their positions reflect the digit values. “BB ROY of Great Britain had a Very Good Wife,” the capital letters represent the first letters of the colors, and their positions represent the digit values.

Question 3: What is the purpose of color labelling resistors?

Ans: Colors are used to designate the value and function of components and wires. Resistor color-coding uses colored bands to quickly identify a resistor’s resistive value and tolerance percentage, with the physical size of the resistor showing its wattage rating.