Table of Contents

The physical segregation of a chemical substance of interest from external or contaminating substances is known as purification. Isolates are the pure outcomes of a successful purifying process. When compounds are extracted from natural sources, they are polluted and combined with additional contaminants such as chemicals, soil, and sand, among other things. To acquire pure compounds, they must first be purified using chemistry-specific purification procedures. The compounds are impure not just when derived from natural sources, but they can also become impure in the laboratory due to side reactions and other contaminations. As a result, purification is an important stage in the extraction or production of any chemical, and it necessitates careful process selection.

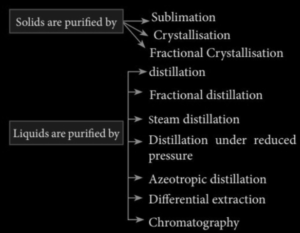

A brief outline

The purity of an organic compound is tested and determined after purification by measuring any of the substance’s physical constants, such as melting and boiling points, refractive index, and so on. Aside from that, spectroscopic and other approaches can be used to determine the purity of an organic chemical after it has been purified.

Purification Techniques

For each extracted component or manufactured material, there are unique purification methods, and the following are some of the most often used and significant purification processes:

- Crystallization and recrystallization

- Filtration

- Fractional distillation

- Simple distillation

- Steam distillation

- Fractional crystallization

- Sublimation

- Differential extraction

- Chromatography

- Distillation at reduced pressure

Methods of purification of organic compounds

Purification of solids

-

Sublimation

Some solids can bypass the liquid phase and move straight to the vapour state. Sublimation is a purifying process that takes advantage of this feature. It aids in the separation of sublimely and non-sublimely chemicals. The substance is heated in a China dish, and the sublime chemicals are collected using an inverted funnel. To speed up the process, the funnel is maintained chilly. The substance’s vapours condense on the funnel.

-

Crystallization

The concept is that the solubilities of the compound and the contaminants in a solvent are different. A solvent is chosen in which the purified chemical is sparingly soluble, that is, sparingly soluble at lower temperatures but soluble at higher temperatures. The solution is heated to a saturated state, and the crystals of the compounds are filtered out after cooling. Crystals of benzoic acid, for example, can be crystallized using water. In cold water, benzoic acid is very slightly soluble; in hot water, it is completely soluble. Repeated crystallization is used if the combination contains impurities with the same solubility as the chemical to be purified.

Purification of liquids

-

Distillation

Distillation works on the concept that a combination of liquids can be separated by the difference in their boiling points. The temperature at which the liquid’s vapour pressure equals air pressure is known as the boiling point. This approach distinguishes between volatile and non-volatile liquids.

-

Fractional distillation

When the difference between boiling points of the liquids isn’t significant, this method is used. Because the vapours of such liquids may condense, a fractionating column is attached to the RB’s mouth.

-

Vacuum Distillation

Because the boiling point is affected by atmospheric pressure, liquids distilled in a lower-pressure atmosphere will boil at a lower temperature than their boiling points. A vacuum pump is used to do this. Because the air pressure is reduced, the liquids boil faster, resulting in a speedier distillation process.

-

Steam Distillation

Steam is passed into the flask containing the liquids to be separated in this type. The idea is that because aqueous tension (water’s vapour pressure) helps to equalize air pressure, liquids will boil faster.

-

Differential extraction

Immiscible liquids, or liquids that do not mix, are treated with this procedure. Oil and water, for example, are incompatible. The immiscible liquids are separated and left undisturbed in a separating funnel. They split after a while based on their respective gravities, with the heavier liquid sinking to the bottom. After that, they are collected.

-

Chromatography

Chromatography is a separation process for separating constituent particles of a mixture of substances, purifying chemicals, and determining the purity of organic molecules. A combination of substances is applied to a stationary phase (solid or liquid) with this approach. On the stationary phase, the gas mixture or pure solvent is permitted to move slowly. As a result, the mixture’s components begin to separate from one another.

There are two types of chromatography:

- Adsorption Chromatography

- Partitions Chromatography

Adsorption Chromatography

It is based on the idea that the elements are absorbed to variable degrees on an adsorbent. Adsorbents such as silica gel or alumina are commonly employed. Different elements of the mixture are adsorbed at varying distances across the stationary phase when a mobile phase passes over it.

Adsorption chromatography is further divided into the following categories:

Column chromatography

A mixture is separated in this step using a glass column packed with silica gel or alumina. At the top, the ingredient with the strongest affinity for the fixed phase is adsorbed, and so on. It is then recovered with the help of an eluant. After that, the solvent is evaporated to obtain the component.

Thin-layer chromatography

A sheet of alumina (0.2 mm thick) is used to cover a small spot of the mixture, which is then stored in a suitable solvent. Due to capillary action, the solvent rises, and the constituents rise with it depending on their differential adsorption, allowing them to be separated.

Colloidal Solution Purification

Electrolyte impurities are common in freshly created colloidal solutions. When electrolytes are present in tiny amounts, they help to stabilize a sol, but when they are present in high amounts, they tend to destabilize the colloidal solution. As a result, it is required to purify colloidal solutions by eliminating any electrolyte impurities that may be present.

The following procedures are commonly used to purify colloidal solutions.

- Dialysis

- Electrodialysis

- Ultrafiltration

- Ultracentrifugation

Significance of methods of purification in NEET exam

It is our objective at Infinity Learn to give students a high-quality, fun, and informative education. We believe in a teaching method that emphasizes not only the theoretical aspects of education but also the practical applications of concepts pertinent to the NEET exam. As a result, Infinity Learn students are able to handle knowledge at a much greater level during live classes. If students are having difficulties or wish to spice up their study sessions, they can use our services.

Frequently Asked Questions

Why do we need to cleanse chemical substances in the first place? What is the procedure for purification?

Chemical compounds found in nature, as well as those created in laboratories, contain impurities in the form of other molecules. Purification techniques are used to obtain the required purity of compounds, as these must be removed in order to obtain pure chemicals.

How can we purify organic substances using sublimation?

Sublimation is the conversion of a solid to a gas without going through the liquid state. This approach can be used to purify compounds that are sublimely or have vapour pressures that equalize to atmospheric pressure well before they reach their melting points.

What criteria are used to determine the purity of organic compounds?

The purity of organic compounds is measured after purifying operations by evaluating physical quantities such as density, melting, and boiling point measurements, as well as chromatographic techniques such as thin-layer chromatography.