Table of Contents

Introduction

The crankshaft is an important component of internal combustion engines. Its principal role is to convert the pistons’ up-and-down action into rotational motion, which powers the engine’s drivetrain.

This article will look at the crankshaft and its different functions, design concepts, and applications. We will study the crankshaft’s purpose in converting reciprocating motion to rotational motion, review its construction design concepts, and investigate its diverse applications in various industries.

In addition, we will discuss the significance of crankshaft materials, the role of counterweights in engine balancing, and the need for optimum lubrication for the engine’s smooth running.

Types of Crankshafts

The crankshaft can be classified into two types based on the position of the crank:

- Overhung crankshaft or side crankshaft

- Crankshaft in the centre

Crankshafts are also classified as single-plane, cross-plane, stroker, billet, forged steel, and cast iron crankshafts. Each category has distinct properties and applications.

Crankshaft Design

The crankshaft is positioned within the engine block and is maintained in place by primary bearings that allow it to revolve within the block. Each piston’s upward and downward motion is transmitted to the crankshaft via connecting rods. In order to smooth out power distribution and reduce vibration, a flywheel is frequently mounted to one end of the crankshaft.

A crankshaft is subjected to immense loads, up to 8.6 tonnes (19,000 pounds) per cylinder in extreme situations. Crankshafts for single-cylinder engines are often simpler in design than crankshafts for multi-cylinder engines.

The crankshaft is meticulously designed to endure the high speeds, mechanical stresses, and temperature loads encountered within the engine.

Crankshaft Position Sensor

The crankshaft position sensor is an important component connected to the crankshaft. This sensor monitors the crankshaft’s position and rotational speed, providing critical information to the engine management system. It allows for precise control of ignition timing and fuel injection, which improves engine performance.

Crankshaft Function

The crankshaft is essential to the engine’s functionality. It converts the pistons’ linear motion into a rotational force, which drives the crankshaft and, ultimately, powers the vehicle. The presence of connecting rods and crank throws allows for this conversion.

Camshaft vs Crankshaft

The camshaft acts differently than the crankshaft, which turns reciprocating action into a rotating motion. The camshaft regulates the engine’s valves, guaranteeing optimal air-fuel mixture intake and exhaust gas expulsion. The crankshaft and camshaft operate in tandem to ensure the engine runs smoothly.

Illustrations and Diagrams

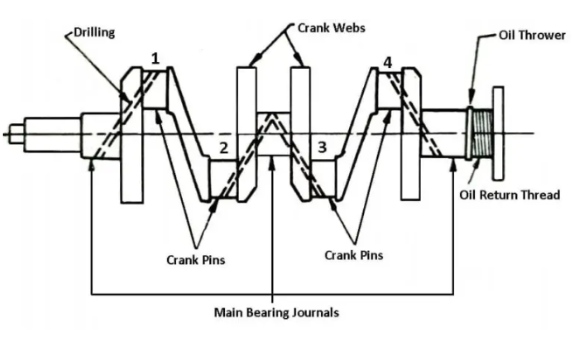

Illustrations and diagrams are visual representations that play a vital role in understanding the intricate details of crankshafts. They provide clear and concise visual explanations of the structure, components, and operation of crankshafts.

These illustrations typically include crankshaft diagram, which depict the main components such as the main journal, crankpin, and counterweights, illustrating their arrangement and relationships.

Additionally, there are crankshaft drawing with dimensions, which provide precise measurements for accurate analysis. Piston-crankshaft diagrams showcase the connection between the piston and the crankshaft, demonstrating how linear motion is converted into rotational motion.

Applications and Significance

Crankshafts are used in various industries, including automotive, maritime, and power generation. Its efficient and dependable performance is critical for excellent engine running, vibration reduction, and fuel efficiency.

Conclusion

Understanding the crankshaft’s function, design, and usage is essential for understanding how internal combustion engines work. The engine is driven by the crankshaft’s ability to transform reciprocating action into rotating motion. With its numerous applications in various industries, the crankshaft remains an important component in the engineering world.

Frequently Asked Questions on Crankshaft

What is a crankshaft?

A crankshaft is a mechanical component found in internal combustion engines that translates the reciprocating motion of the pistons into a rotating motion, thereby supplying power to the engine.

What are the three parts of the crankshaft?

The prominent journal, crankpin, and crank arm are the three major components of the crankshaft. These three parts of the crankshaft combine to convert the pistons' linear motion into a rotating one.

What are the five parts of the crankshaft?

The primary bearing journals, crankpins, crank cheeks, counterweights, and flange are the five major components of the crankshaft. Each component serves a distinct purpose and contributes to the overall operation of the crankshaft.

What happens if the crankshaft is damaged?

If the crankshaft is damaged, it might cause serious engine issues. Vibrations, loss of power, misalignment of engine components, and even engine failure can be caused by a broken crankshaft. In most circumstances, repair or replacement is required.

What causes crankshaft failure and can a crankshaft be repaired?

Crankshaft failure can be caused by several factors, including improper lubrication, excessive heat or pressure, incorrect assembly, poor maintenance, and manufacturing defects. Depending on the extent of the damage, a crankshaft can sometimes be repaired through processes like grinding or welding. However, severe damage often requires the replacement of the crankshaft with a new one.