Table of Contents

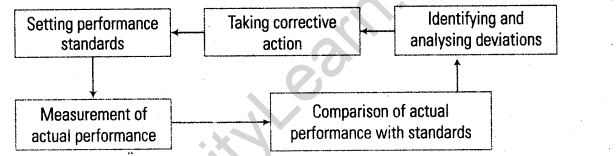

Steps in the Process of Controlling

Important Questions for CBSE Class 12 Business Studies

1. Steps in the Process of Controlling

(i)Setting performance standards Controlling starts with setting standards, against which actual results are to be evaluated.

(ii)Measurement of actual performance In this step, the actual performance of activities is measured.

(iii)Comparing actual performance with standards Now the actual performance is compared with the standards set to find the deviations.

(iv)Analysing deviations Under this step, deviations of significant nature need to be identified. For this a range of deviations should be established as the deviations in the key areas of business need to be attended on urgent basis as compared to deviations in certain insignificant areas. Critical point control and management by exception should be adopted in this regard.

(v)Taking corrective measures This is the final step, in which manager takes the corrective action according to set plans.

Previous Year Examination Questions

1 Mark Questions

1.Give the meaning of ‘critical point control’. (Foreign 2014)

Ans. Control should focus on Key Result Areas (KRAs). Which are critical to the success of an organisation. Therefore, each and every activity should not be controlled and only focus should be on critical points.

2.What is meant by ‘management by exception’ in the process of controlling?

(Compartment 2014)

Ans. ‘Management by exception’ is an important principle of control, which propagates that only significant deviations which goes beyond the permissible limit should be brought to the notice of management, as an attempt to control everything, results in controlling nothing.

3.What should be done while ‘taking corrective actions’ in the process of controlling when especially in the important areas, deviations go beyond the acceptable range? (Delhi 2013)

Ans. Immediate managerial attention is required if the deviations go beyond the acceptable range in important areas. After the analysis of deviations and their causes, the task is to remove the hurdles from the actual work plan. The purpose of this step is to bring the actual performance upto the level of expectations by opting corrective measures.

4.What is important while analysing deviations in controlling? (Delhi 2011)

Ans. While analysing deviations, it is important to determine the acceptable range of deviations/KRA (Key Result Areas).

5.What should be the focus point for a manager while controlling, as controlling at each and every step is not possible?(All India 2011)

Ans. Focus on Key Result Areas (KRAs), which are critical to the success of an organisation.

6.Why is actual performance compared with standards in the process of controlling?

(Delhi 2010; All India 2010,2009)

Ans. While performing the function of controlling, a manager compares the actual work performance with the standards. He tries to find out whether the actual performance is more or less than the standards and find out the deviations, if any.

Also Read: Class 12 Math NCERT Solutions – NCERT Solutions for Class 12 Maths

4 / 5 Marks Questions

7.Controlling is a systematic process involving a series of steps. State the steps involved in the process. (Compartment 2014; All India 2014,2011,2008)

or

Explain the various steps involved in the process of controlling. (Delhi 2011 c)

or

Explain the process of controlling. (Delhi 2010)

Ans. Controlling is measuring and correcting the activities of subordinates to ensure that events confirm to plans. It is a systematic process involving a series of steps, which are as follows:

(i)Setting performance standards The first step in the controlling process is to set the performance standards. Standards are those criterias, on which the actual performances are measured. These standards serve as a benchmark towards which an organisation strives to work.

(ii) Measurement of actual performance After the establishment of standards, the next step is measuring the actual performance with the set standards. This can be done by opting several methods like personal observation, sample checking, performance reports, etc.

(iii) Comparison of actual performance with standards In this step, the actual performances are compared with the established standards. Such comparisons reveal the deviation between planned and actual results.

(iv) Analysing deviations At this stage, acceptable and non-acceptable deviations areanalysed where following things are noticed:

- Critical point control It means keeping focus on key result areas where deviations are not acceptable and it should be attended on the priority basis.

- Management by exception It means if a manager tries to control everything, it may end up in controlling nothing. Thus, he should first handle the significant deviations, which require his priority.

(v) Taking corrective action The most important step in the controlling process is taking corrective actions. After the deviations and their causes are analysed, the task is to remove the hurdles from the actual work plan. The purpose of this step is to bring the actual performance up to the level of expectations by opting corrective measures.

8.After setting the performance standards, the next step in the controlling process is the ‘measurement of actual performance’. Explain this step in the process of Controlling. (All India 2013)

Ans. Measurement of actual performance Once the standards of desired performance are fixed, the next step is to measure the actual performance. Performance should be measured in same terms, in which standards have been established. Comparison of performance with standards is comparatively easier when the standards are expressed in quantitative units.

This will also facilitate comparison, e.g. if the standard for a factory has been laid down as 500 tons per month, the monthly output of the factory should alsc be measured in tons. There are several techniques for measurement of performance. These include personal observation, sample checking, performance reports, etc.

9.Explain how ‘management by exception’ helps in the controlling process.(All India 2013)

Ans. It is an important principle of management control based on the belief that an attempt to control everything results in controlling nothing. This is known as ‘control by exception’. Thus, only significant deviations which go beyond the permissible limit should be brought to the notice of management. An attempt t:o go through all deviations tend to increase unnecessary efforts and to decrease attention on important problems.

10.Explain how ‘critical point control’ helps in the controlling process. (Allindia2013)

Ans. Small deviations in certain areas may have greater significance than larger in other areas. According to this principle, control should focus on Key Result Areas (KRAs), which are critical to the success of the organisation. When anything goes wrong in these areas, the entire organisation suffers, e.g. a 2% increase in labour cost is much more harmful than a 5% increase in postal charges.

11.Seeta, Geeta and Babita Ltd is engaged in manufacturing machine components. The target of production is 250 units per day per worker. The company had been successfully attaining this target until two months ago. Over the last two months, it has been o bserved that daily production varies between 200-210 units per worker.

(i) Name the function of management and identify the step in the process of this function which helped in finding out that the actual production of a worker is less than the set target.

(ii) To complete the process of the function identified in and to ensure the performance as per set targets, explain what further steps a manager has to take. (All India 2010)

or

Kapil and Kamal Company is a large manufacturing unit. Recently, the company had conducted time and motion studies and concluded that on an average, a worker could produce 300 units per day. However, it has been noticed that the average daily production of a worker is in the range of 200-225 units.

(i)Name the function of management and identify the step in the process of this function which helped in finding out that the actual production of a worker is less than the set target.

(ii)To complete the process of the function identified in and to ensure the performance as per time and motion studies, explain what further steps a manager has to take.(HOTS; Delhi 2010 C)

Ans. (i) The management function which helps in finding out that the actual production of a worker is less than the set target is known as controlling. Here, comparing actual performance with standards or appraisal of performance is the step involved in the process of controlling.

(ii) A manager has to take following steps to complete the process of controlling:

- Analysing deviations Deviations can be due to multiple reasons like unrealistic standards, defective process, in adequacy of resources, environmental factors, etc.

- Taking corrective actions The final step in the control process is taking appropriate actions so that deviations may not occur again and the objectives of the organisation are achieved. It may also necessitate reforming the process of selection and training of workers. Thus, controlling may require change in all other managerial functions.