Table of Contents

Introduction to Pressure Transducer

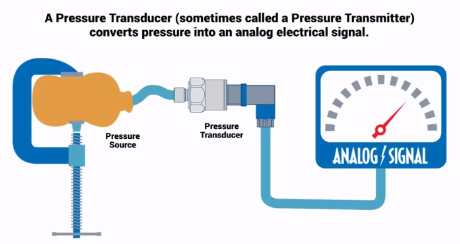

In the world of engineering and technology, pressure transducers play a vital role in various industries. They are essential devices that convert pressure variations into electrical signals, enabling precise pressure measurement and control.

Pressure transducers are critical devices that enable accurate pressure measurement and control in numerous applications. With their diverse working principles and types, they offer flexibility and reliability in different industries. Pressure transducer in Hindi is written as प्रेशर ट्रांसमीटर.

This article explores the working principle, different types, applications, and other aspects of pressure transducers.

Pressure Transducer: An Overview

A pressure transducer sensor, also known as a pressure sensor, is a sophisticated electronic device used to measure and convert pressure into electrical signals. These signals can be further processed, displayed, or recorded by various control systems, making pressure transducers valuable tools in a wide range of applications. A pressure transducer price depends upon the model we are choosing.

Pressure Transducer Working Principle

The pressure transducers working principle is based on the concept of piezoelectricity or piezoresistivity. Piezoelectric pressure transducers utilize a crystal element that generates an electric charge when subjected to mechanical stress or pressure.

On the other hand, piezoresistive pressure transducers utilize a resistive element that changes its electrical resistance in response to pressure. Both principles allow the transducer to convert pressure changes into electrical signals, which are then calibrated to provide accurate pressure readings.

Pressure Transducer Diagram

The pressure transducer diagram is shown below:

Pressure Transducer Kit

The pressure monitoring kit with a disposable pressure transducer is intended for use on patients who require intravascular, intracranial, blood pressure monitoring, intrauterine pressure monitoring, intraabdominal pressure monitoring, and other similar procedures.

Pressure Transducer Types

There are various pressure transducer types, as follows:

- Strain Gauge Pressure Transducers: These transducers use strain gauges to measure the deformation caused by pressure and convert it into electrical signals.

- Capacitive Pressure Transducers: These transducers utilize the variation in capacitance due to pressure changes to measure and convert pressure.

- Piezoelectric Pressure Transducers: These transducers employ piezoelectric crystals to generate electrical charges in response to pressure variations.

- Piezoresistive Pressure Transducers: These transducers use a resistive element that changes its resistance with pressure to produce electrical signals.

- Optical Pressure Transducers: These transducers use optical principles to measure pressure variations and convert them into electrical signals.

Applications of Pressure Transducers

Pressure transducers find extensive applications across various industries and fields, some of which include:

- Industrial Automation: Pressure transducers are used in industrial automation to monitor and control pressure in manufacturing processes.

- Aerospace and Aviation: They are used in aircraft and spacecraft for altitude measurement, cabin pressure monitoring, and more.

- Automotive: Pressure transducers are employed in automotive systems, such as tire pressure monitoring and engine management.

- Medical: They are used in medical devices like blood pressure monitors and respirators.

- Environmental Monitoring: Pressure transducers play a role in monitoring environmental conditions, such as water level measurement and weather forecasting.

- Oil and Gas: They are used in oil and gas industries for well pressure monitoring and pipeline management.

- Research and Development: Pressure transducers are valuable tools in research and development labs for various experiments and studies.

Frequently Asked Questions on Pressure Transducer

What is the working principle of a transducer?

The working principle of a transducer involves converting one form of energy into another. In the case of pressure transducers, they utilize piezoelectric or piezoresistive principles to convert mechanical pressure into electrical signals, enabling precise pressure measurement.

What is 4-20mA pressure transducer?

4-20mA pressure transducer is a type of pressure transducer that provides an output signal in the form of a current loop, where 4 mA represents the minimum pressure and 20 mA represents the maximum pressure. This type of transducer is commonly used in industrial applications for its simplicity and reliability.

What is the working principle of pressure sensor?

The working principle of pressure sensors, including pressure transducers, involves the use of piezoelectric crystals or resistive elements to sense the pressure-induced mechanical changes. These changes are then converted into electrical signals, which can be calibrated to provide accurate pressure readings.

What type of sensor is a pressure transducer?

Pressure transducer sensor specifically measures pressure variations and converts them into electrical signals. Depending on the application, pressure transducers can use various working principles such as strain gauge, capacitive, piezoelectric, or piezoresistive to achieve accurate pressure measurement.

What are the three types of transducers and What are the three components of a transducer?

The three main types of transducers are active transducers, passive transducers, and digital transducers. The three components of a transducer are the sensing element, signal conditioning circuit, and output interface.