To Observe and Explain the Effect of Heating on a Bi-Metallic Strip

Aim

To observe and explain the effect of heating on a bi-metallic strip.

Apparatus

A bi-metallic strip (made of iron and brass bars), a board with clamp screw on one side and vertical scale on the other side, electric heating arrangement, or a burner thermometer.

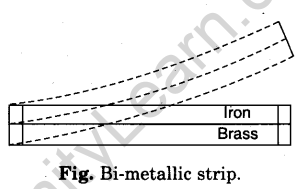

Short Description of a Bi-metallic Strip

It is a strip made up of two bars of different metals but same dimensions, put together lengthwise and ripetted at their ends. The strip is straight at room temperature.

When the bi-metallic strip is heated both bars expand differently. Since they are ripetted at their ends, their ends stay together. The bi-metallic strip bends keeping more expanding bar on its convex side. More is heating, more is the bending.

In case of an iron-brass bi-metallic strip, the bent strip will have brass bar on its convex side.

Theory

If two rods of different metals have same length L1 at temperature t1°C, their length at higher temperature t2 °C will be different. The rod of a metal having more value of ‘ coefficient of linear expansion will have more length than the other rod.

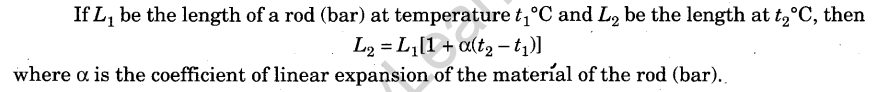

Diagram

Procedure

- Clamp one end of the brass-iron bi-metallic strip, keeping brass bar on the lower side.

- Keep the strip horizontal rested on a vertical support.

- Fix a vertical scale near the free end of the bi-metallic strip.

- Suspend a thermometer with its bulb touching the strip in the middle.

- Note the initial temperature of the strip.

- Note the vertical scale division coinciding with the upper edge of the strip.

- Heat the strip by passing electric current through it or by using a burner. The thermometer will show a rise of temperature.

- Watch the movement of the free end of the strip. The strip bends upwards (towards iron bar side) and position of upper edge of the strip changes.

- Note the temperature after each rise of temperature by 2°C and also the position of the upper edge at that temperature.

- Record your observations as given below.

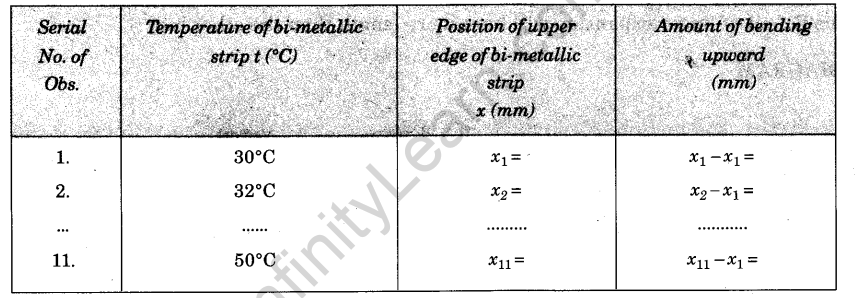

Observations

Room temperature = 30°C (say)

Least count of vertical scale = 1 mm.

Table for temperature and vertical scale reading

Calculations

- Find the amount of bending by taking difference of position with initial position.

- It is found that amount of bending increases as temperature rises.

Result

- Bi-metallic strip bends more and more as its temperature rises.

- Since brass bar is on convex side and iron bar on concave side of bent bi-metallic strip, brass bar expands more than the iron bar. Hence brass has larger linear expansion.

Precautions

- The two bars should be firmly ripetted near their ends.

- Brass bar should be kept on the lower side.

- One end of the bi-metallic strip should be screw clamped.

- Heating of whole bi-metallic strip should be uniform.

Sources of error

- The ripettes may be loose.

- Heating of strip may not be uniform.